- Alignment Tester

- Brake Tester

- Jack Stands

- High Service Stands

- Service Jacks

- Trailers - Closed & Open

|

BBB Rating |

- Trailex

- Weaver Jack

- Weaver Safety Lanes

- Nationwide

- Direct Shipping

|

|

|

|

|

||

| 888-274-8490 |

|

![]()

![]()

Seal Kits for Weaver Jacks

![]()

|

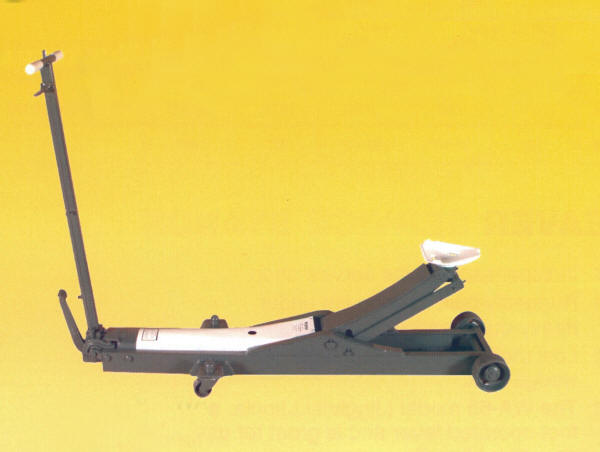

Weaver WA-73B Four (4) Ton Long Chassis

Hydraulic Service Jack

How Can I Identify My Jack?

Using the following Dimension Chart, - Compare Features and Measurements

| MODEL |

CAP. (tons) |

FRONT WHEELS |

SADDLE STYLE AND SIZE |

FRAME LENGTH |

JACK WEIGHT |

| WA-72B | 2 | Two - 4" Diameter | Triangular or Round 5"' to 6" |

51" | 136 lbs |

| WA-73B | 4 | Two - 5" Diameter |

Triangular or Round 5" to 6" |

58" | 212 lbs |

| WA-75B | 10 | Two - 7" Diameter | Round 9" |

66" | 356 lbs |

| WA-85 | 20 | Three- 7" Diameter | Square 7" |

69" | 531 lbs |

How Can I Identify My Jack Model Number?

Using the following Description Chart, - Determine Whether You Have an A or B

Model

| MODEL | CAP. TONS | CYLINDER DESCRIPTION | KIT # |

| WA-72A | 2 | Head of cylinder is held down

by TWO Cotter Keys |

KJ-106 |

| WA-72B | 2 | Head of cylinder is held down by Metal Tabs |

KJ-106 |

| WA-73A | 4 | Head of cylinder is held down by TWO Cotter Keys |

KJ-107 |

| WA-73B | 4 | Head of cylinder is held down by Metal Tabs |

KJ-107 |

| WA-75A | 10 | Head of cylinder is held down by A Large Pin Through The Frame |

KJ-108 |

| WA-75B | 10 | Head of cylinder is held down by TWO Bolts Inside Frame |

KJ-108 |

| WA-85 | 20 | Head of cylinder is held down by TWO Bolts Inside Frame |

KJ-109 |

If Your Jack Looks like a Weaver Jack, but it has a

different Manufacturers Label on it -

Some Manufacturers Private Label Weaver Jacks for sale under their Name -

Contact Us - We can assist you in Identifying your Jack.

Weaver 20 ton Hydraulic Service Jack Model WA-85

WA-72B (2 ton) WA-75B (10

ton) WA-73B (4 ton)

|

|

KJ-106 Seal Kit for Weaver WA-72B 2 Ton Jack |

KJ-107 Seal Kit for Weaver WA-73B 4 Ton Jack |

|

| Contains: S-6654 Piston Packing (3) S-22961 Cylinder Cap Gasket S-6016 Piston Ram Cup S-7265 Pump Cup S-7492A Pump Packing (3) 1-1/2"O.D.* S-17829 Large "O" Ring S-15047 Small "O" Ring S-2594 Ball Chamber Gasket S-2750 Ball 1/2" S-2505 Ball 5/16" S-2499 Cotter Pin (2) S-3234 Cotter Pin *Note: Older style WA-72 Jack requires additional parts. If the rear of the cylinder is a casting which is held down by TWO Cotter Keys - it is an old style Order the following Additional Parts: Qty 3 ea S-7492 Packing 1-1/8" O.D. (New Style is a Machined Block which is held down by Metal Tabs) |

Contains: S-6614 Piston Packing (3) S-22962 Cylinder Cap Gasket S-4714 Piston Ram Cup S-24648 Pump Cup S-7412 Pump Rod Packing (3) S-17829 Large "O" Ring S-15047 Small "O" Ring S-2594 Ball Chamber Gasket S-2750 Ball 1/2" S-2505 Ball 5/16" S-2499 Cotter Pin (2) S-3234 Cotter Pin |

|

|

KJ-108 Seal Kit for Weaver WA-75B 10 Ton Jack |

KJ-109 Seal Kit for Weaver WA-85 20 Ton Jack |

|

Contains: S-6615 Piston Rod Packing (3) S-22963 Cylinder Cap Gasket S-24649 Piston Ram Cup S-24648 Pump Cup S-7412 Pump Rod Packing (3) S-17829 Large "O" Ring S-15047 Small "O" Ring S-5125 Ball Chamber Gasket S-5122 Ball 5/8" S-3282 Ball 3/8" S-3083 Cotter Pin S-24703 Teflon Ring |

Contains: S-16022 Piston Rod Packing (3) S-22964 Cylinder Cap Gasket S-16023 Piston Ram Cup S-24648 Pump Cup S-7412 Pump Rod Packing (3) S-17829 Large "O" Ring S-15047 Small "O" Ring S-5125 Ball Chamber Gasket S-5122 Ball 5/8" S-3282 Ball 3/8" S-3083 Cotter Pin |

| INSTALLATION INSTRUCTIONS FOR WEAVER SEAL KITS | |

|

These Jack Cylinder Service

Kits are for minor cylinder repairs only, if additional servicing is

required have repairs performed by a qualified hydraulic jack repair

center. |

|

|

Use Safety Solvent or Mineral

Spirits to clean parts—blow dry with compressed air. Do not use Gasoline, lacquer thinner or any other solvents as these will damage the seals. |

|

| Use AW-32 Light Hydraulic Oil (or oil that meets MIL•F•17111 011 specifications) | |

|

|

|

|

To Remove The Cylinder

1. Remove the cotter pin

(pins) or bolts in the cross head.

2. Remove the cotter and pin

in the pump.

3. Remove the cotter and pin

in the release yoke.

4. Place cotter key in while

depressing foot pedal.

5. Raise the lifting arm by

means of the saddle bracket, and place a block of wood between the arm

and frame to hold up the arm.

6. This releases the cylinder

at the forward end, so that it may be removed as a complete unit, for

service. |

|

|

|

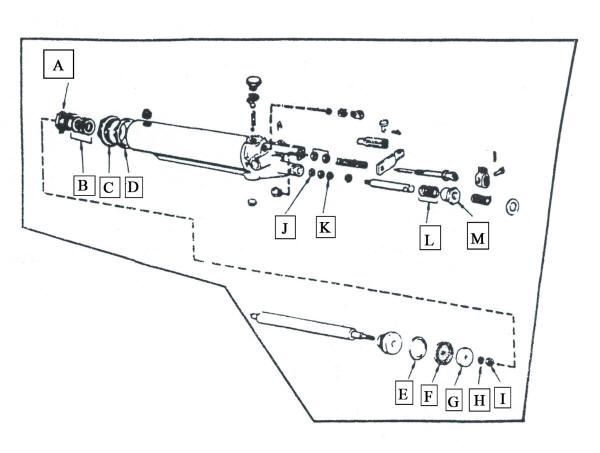

| Piston and Pump Assembly Derail for Weaver Jack Cylinders | |

|

Ram Cup Replacement |

|

To Replace The Piston Ram Cup:

1. After removing the cylinder

unit as described above, place it in a vise.

Note that the vise jaws should

grip the steel block, not the

steel cylinder. Set the unit in the vise with the steel cylinder and

piston up. Remove the vent plug. Drain

the oil.

2. Remove the Packing Nut [A]

and three Packings [B] .Unscrew the cylinder cap [C] and lift the piston

out of the cylinder.

3. Remove the nut [I], Lock

Washer [H], and washer [G] which holds the cup [F] at the end of the

piston--put in the new cup [F], and replace the nut and washer.

(The Backup Teflon Ring [E] is

only used on certain – but not all WA-75A models only)

Either peen the threads with a punch or use a thread locking

compound to prevent nut from loosening.

4. In fitting the new cup into

the cylinder, USE GREAT CARE

as the cup passes the filler plug hole not to cut or otherwise damage

the cup. Lubricate the cup with

hydraulic oil when assembling.

5. Replace the Cylinder Cap

[C] and Gasket [D] -- install the 3 new Packings [B]

and the Packing Nut [A].

|

|

|

CAUTION

Excessive friction, chatter

and binding will occur if the cup nut is pulled down too tightly.

TIP

This means that you use only enough pressure to close the spring lock

washer [H]. Do not tighten

until the cup heel begins to extrude (swell) as this may cause problems

When servicing a jack with a

synthetic cup, it may appear that the nut has become loosened, but this

is not necessarily true. It is only necessary to hold the cup against

the ram with slight pressure to prevent leakage. |

|

|

Pump Cup Replacement |

|

To Replace The Pump Cup (small cup):

1. Turn the cylinder unit pump

end upward in the vise.

2. Unscrew the packing nut [M]

- Remove three Packings [L] and pull out the pump plunger.

Remove the Nut [J] that holds

Cup [K] to the end of plunger; insert new cup, new packings and replace

the nut and washers. |

|

|

|

| Release Valve Group and Ball Valve Assembly Derail for Weaver Jack Cylinders | |

|

Ball Valve Replacement |

|

Ball Valve Replacement

1. Remove the Ball Chamber

Plug [V]. Remove the Two

Balls [X&Z] and the Ball weight [Y].

2.

Reassemble with the two new Balls [X&Z], New Plug Gasket [W] and

Ball Weight [Y] (reuse the existing Ball weight).

Ball Weight is installed between the two balls.

IMPORTANT:

Whenever it is necessary to loosen or remove the Ball Chamber Plug, the

Gasket [W] should be replaced with a new one. Oil leakage at this point

is usually caused by trying to reuse an old gasket over again. |

|

|

Release Valve Packing

Housing "O"-Ring Replacement |

|

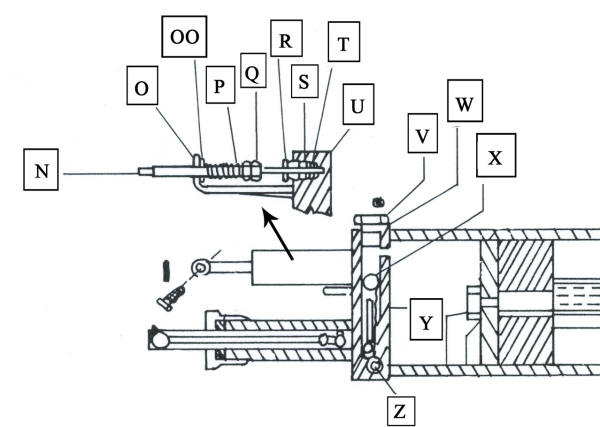

Release Group Needle Valve Packing “O” Rings Replacement

1.

Measure accurately the distance

from the Bracket [O] to the first Nut [P] on the compression spring.

Write this measurement down.

(This is approximately 2 inches)

2.

Loosen the Packing Nut [R].

Remove Nuts [P] & [Q], the Spring, the Valve Rod [N] , the Valve

Guide [OO] and the Packing Nut [R].

It is not necessary to remove the rod clevis.

3.

Remove the Packing Housing [S] and replace the two “O” rings

[T&U]. Now reinsert the

Packing Housing [S]. Reassemble

the Needle Valve and parts with the Packing Nut [R] tightly secured.

4. Tighten the adjusting nut

[P] to the original dimension

that you wrote down and lock this nut with Nut [Q]. |

|

|

|

| Release Valve Group (upper ) - Pump Assembly (lower) | |

| Release Group - Needle Valve Adjustment | |

|

Release Group Needle Valve Adjustment:

In the release group

assembly, the spring governs the load that the Jack will lift.

When the pressure within the cylinder overcomes the spring

tension then the release valve floats off the seat.

It is Imperative that the release valve floats freely in the

release group assembly. To check- use your forefinger and thumb to grasp

the release valve where the release clevis pin passes thru, and wiggle

from side to side. There should be a minimum of .002 to.004 clearance in

the Release Vale Guide [OO]. If no movement is noted, follow these

steps:

Measure accurately the

distance from the Bracket [O] to the first Nut [P] on the compression

spring. Write this measurement

down. (This is approximately 2 inches)

Remove Nuts [P] & [Q],

the Spring, the Valve Rod [N] and the Valve Guide [OO].

It is not necessary to loosen the Packing Nut.

Next,

insert the Valve Rod [N] thru

the Bracket’s [O] opening, slide the

Release Valve Guide [OO] onto the rod, but not seated in the hole,

and insert the rod [N] into the Packing Nut’s [R] opening.

Gently

Tap the end of the release rod [N] with a hammer until it stays firmly

seated in the internal needle seat.

Slide the Release Valve Guide [OO] towards the Bracket [O]

(normally it will smoothly fit into the bracket hole) and then noting

where the center alignment of the rod in the bracket hole is off -- Tap

the welded bracket accordingly with a hammer to gently bend the bracket

and correct the misalignment. It is in alignment when you can smoothly

slide the Valve Guide into the Bracket’s hole.

Reassemble the Release Valve

and parts. Tighten the

adjusting nut [P] to the original

dimension that you wrote down and lock this nut with Nut [Q] and

then test the Jack for proper operation.

|

|

|

|

|

|

Troubleshooting See the Operations and Service Manual CLICH HERE |

|

|

Print a

Copy of these Seal Kit Instructions CLICK HERE |

copyright 1997-2014

Castle Equipment Co.